Production technology of glass window film

Nowadays, glass is more and more favored by consumers, not only frosted glass, hot melt glass, stained glass and other decorative effect of strong art glass, there are also a variety of functional glass, such as acoustic noise reduction of laminated glass, insulating glass and heat-retardant fire-resistant glass and so on. This article will introduce the glass window film using which production technology, as well as what are the benefits of using window film, to help you broaden your horizons.

I. Manufacturing Technology for Window Film

1. Dyeing process

Through the coating composite process will be mixed with dyes in the adhesive coated on PET

or between two layers of PET film, PET substrate coloring, according to the need to make it show

different colors. Advantages are color variety, simple process, low cost; disadvantages are not resistant

to ultraviolet radiation, easy to fade, shelf life is not long.

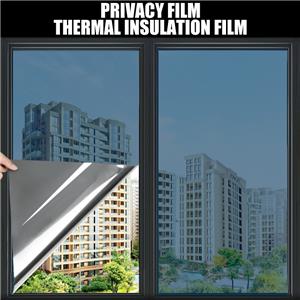

2. Vacuum Spray Plating Technology

Vacuum evaporation coating through the application of thermal evaporation

(for low melting temperature of pure metal) process, the film can be plated on a variety of metals,

alloys or oxide coatings. Vacuum deposition process is usually coated with pure aluminum,

and can be made into different visible light transmittance and reflectivity of the film, so that the film

has sunlight control properties.

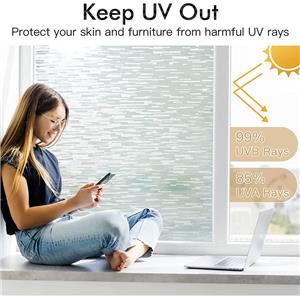

3. Magnetron sputtering technology process

Magnetron sputtering coating method is an advanced process developed in the late 1970s,

it is in a special vacuum equipment, under the action of electrical energy, a variety of metal or metal

synthetic target charged ion impact, made of multi-layer dense low reflection and high thermal

insulation of the metal film layer, orderly and uniformly coated on the surface of the substrate,

and composite process to make a wide variety of unique and stable color, high level of transmission

rate Selectivity, to ensure that the product has sufficient toughness, explosion-proof, heat insulation,

anti-UV 99%, long shelf life. Compared with the traditional vacuum spray plating process,

magnetron sputtering process has many advantages, such as stronger adhesion of the plating

layer and the substrate; can be conveniently made of high melting point substances of the film;

in a large area of continuous substrate can be made more uniform film; easy to control the

composition of the plating layer, can be made of a variety of different compositions and ratios of

alloy coatings.

The principle of magnetron sputtering process is to send the substrate into the vacuum chamber

equipped with magnetron cathode and sputtering gas (argon), cathode plus negative voltage,

glow discharge in the vacuum chamber, resulting in plasma, due to the negatively charged metal

target, positively charged gas ions in the plasma are accelerated, and equivalent to the target of

the target more than the drop in the energy of the target surface, the atoms will bombard the metal

target out of the substrate to precipitate on the surface and form a Metal film.

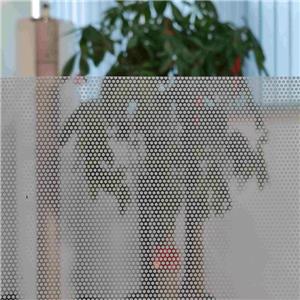

4. Lamination composite process

Glass window film is a multi-layer functionalized polyester composite film material, through the

adhesive, the different functions of the thin layer composite together, so as to make it with

explosion-proof, heat insulation, security features.

Only high better coating system, to ensure that the glass window film in the manufacturing

process, a variety of process parameters are effectively controlled.