Security film identification method

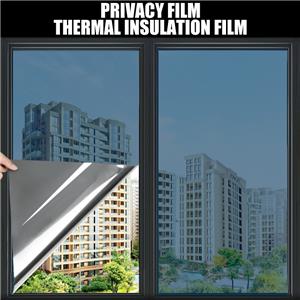

First look at the color, master experts pointed out that high-quality security film using a metal magnetron sputtering process, nickel, silver, titanium and other high-grade metal coated in the optical pole PET substrate, how to use will not appear to lose color, fading phenomenon, and generally for the original color of the metal, will not add any chemical dye. And ordinary dyeing type security film held on the ground gently wipe, there will be fading phenomenon.

Second smell taste, poor quality safety film adhesive layer residual solvents, benzene content is high, there will be odor, and good safety film has been professionally handled before leaving the factory, odor is small. Master safety film experts remind, long time smell this odor, will seriously affect the owner's health.

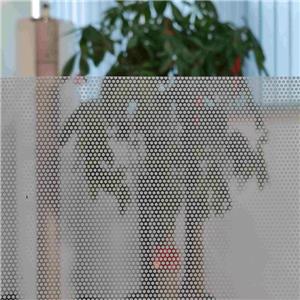

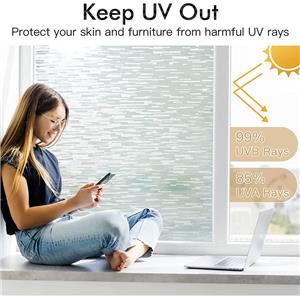

The third indicator, the so-called safety film, must have heat insulation, explosion-proof, UV protection and other effects. Therefore, when choosing, you can consult the sales staff in detail about the situation, so as to determine the quality of the true and false and good and bad.

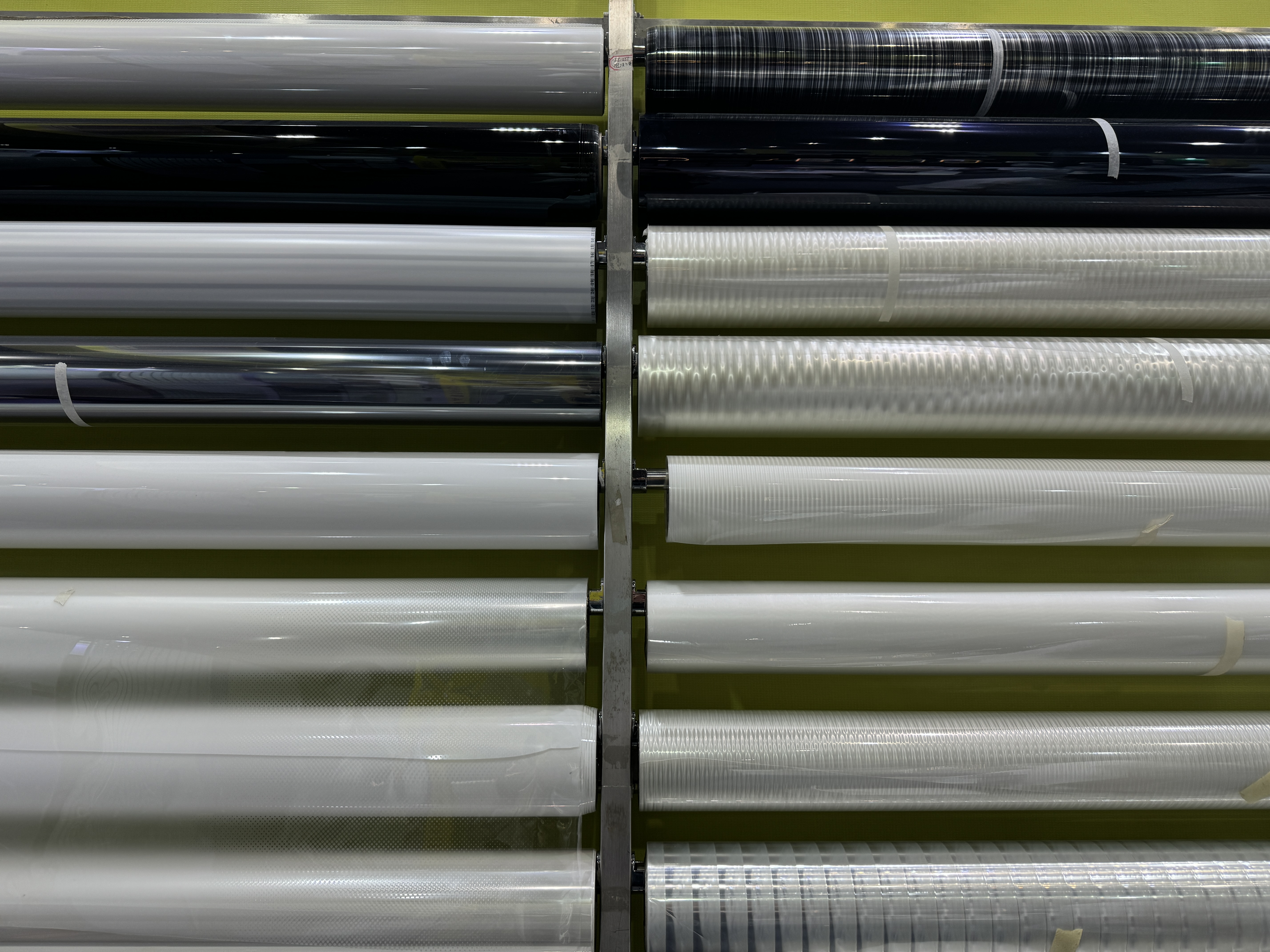

The fourth touch feel, the general thickness of the security film is not less than 2.5 millimeters, so touch feel thick and smooth. In addition, because its surface is hardened, generally will not scratch the surface. The ordinary dyeing type security film due to the thickness is not enough, feel thin and brittle, in the process of shaking the glass, will leave scratches on the security film, seriously affecting the aesthetics.